Factory selling Gate Valve Dn100 - DIN3352-F4 NRS Brass Gland Resilient Seated Gate Valve, DN50-DN1200 – Hongbang

Factory selling Gate Valve Dn100 - DIN3352-F4 NRS Brass Gland Resilient Seated Gate Valve, DN50-DN1200 – Hongbang Detail:

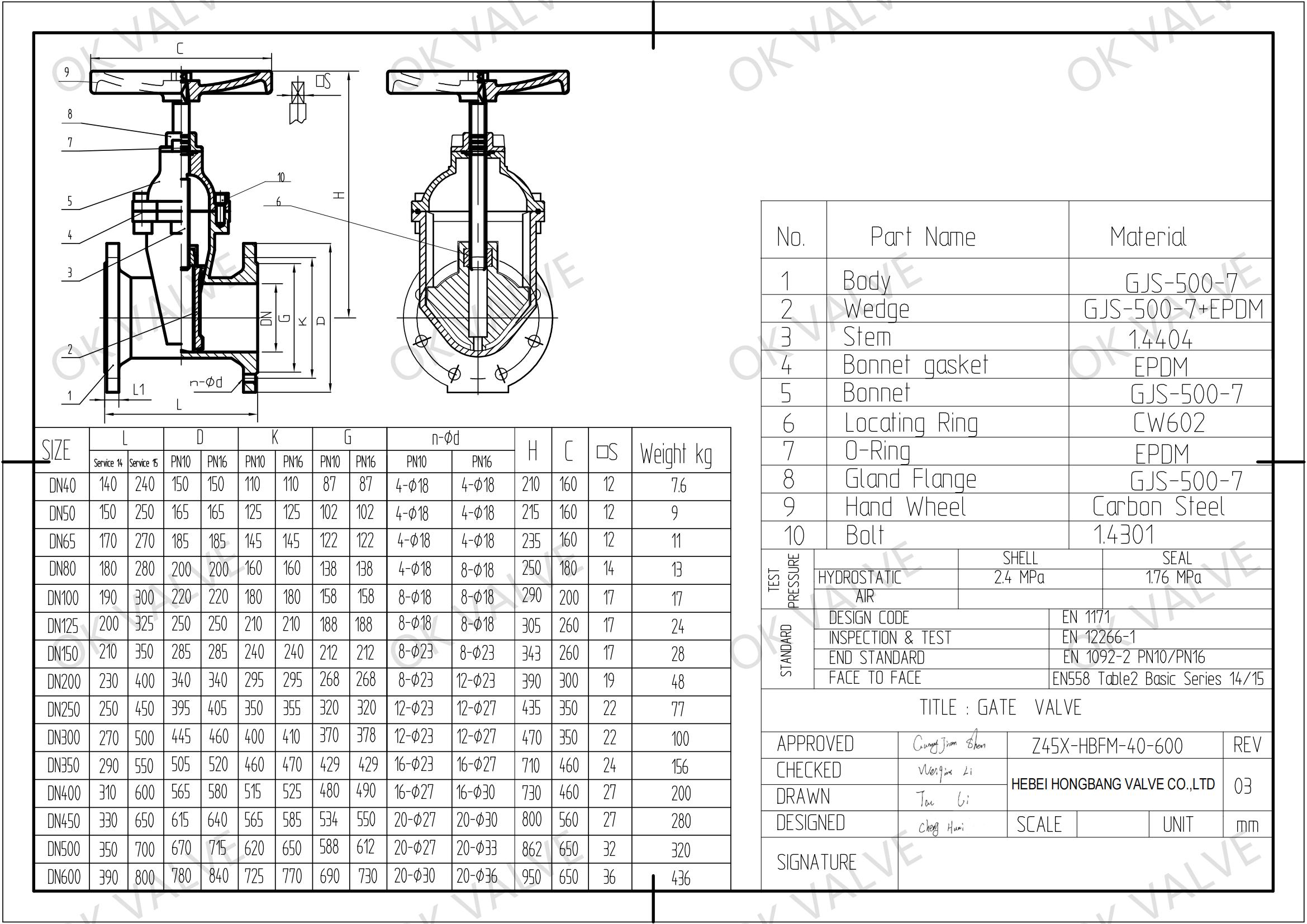

DIN3352-F4 NRS Brass Gland Resilient Seated Gate Valve, DN50-DN600

Features

² The ductile iron core is fully vulcanized with EPDM rubber, no iron parts are exposed to the medium and the excellent rubber vulcanization prevents creeping corrosion underneath the rubber.

² Guides in the wedge and on the valve body ensure a uniform closure, safe operation ensured as the guides prevent overloading of the stem.

² Stainless steel stem with rolled threads for high strength.

² The valve can replace stem seals under pressure.

² Full bore.

² Body inside and outside fusion bonded epoxy coating with excellent corrosion resistant performance.

Standard

| Design standard | DIN3352 F4, EN1171 |

| Flange drilling standard | EN1092-2 PN10/PN16 |

| Face to face standard | EN558-1 Series 14 |

| Hydraulic test standard | EN1074-1 and 2 /EN12266 |

| Seat:1.1*PN(in bar), Body:1.5*PN(in bar) |

Technical Parameters

| Nominal diameter(mm) | 40~600 | 40~600 | |

| Nominal pressure(Mpa) | 1.0 | 1.6 | |

| Testing pressure | Shell(Mpa) | 1.5 | 2.4 |

| Seal(Mpa) | 1.1 | 1.76 | |

| Suitable temperature | -40°C~150°C | ||

| Suitable medium | Drinking water、sewage、seawater、irrigation,or other neutral liquid. | ||

Main Raw Material

| 1 | Body | Ductile Iron | 9 | Top-nut | Brass |

| 2 | Wedge | Ductile Iron+EPDM | 10 | Washer | PTFE |

| 3 | Stem | Stainless steel | 11 | Thrust collar | Brass |

| 4 | Wedge Nut | Brass | 12 | Washer | PTFE |

| 5 | Bonnet | Ductile iron | 13 | Dust Cover | NBR |

| 6 | Bonnet gasket | EPDM rubber | 14 | Handwheel | Ductile Iron |

| 7 | Bonnet | Ductile Iron | 15 | Bonnet bolt | Steel gr.8.8 |

| 8 | O-ring | EPDM rubber |

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Factory selling Gate Valve Dn100 - DIN3352-F4 NRS Brass Gland Resilient Seated Gate Valve, DN50-DN1200 – Hongbang , The product will supply to all over the world, such as: Nigeria, Saudi Arabia, Cambodia, With a wide range, good quality, reasonable prices and stylish designs, our solutions are extensively used in beauty and other industries. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Write your message here and send it to us